HOW TO KNOW ORIGINAL SAFETY FOOTWEAR OR SAFETY BOOTS

What should I know about safety footwear?

How is footwear selected?

Footwear must be

chosen based on the hazards that are present. Assess the workplace and work

activities for:

- Materials handled or used by the worker.

- Risk of

objects falling onto or striking the feet.

- Any material

or equipment that might roll over the feet.

- Any sharp or

pointed objects that might cut the top of the feet.

- Objects that

may penetrate the bottom or side of the foot.

- Possible

exposure to corrosive or irritating substances.

- Possible

explosive atmospheres including the risk of static electrical discharges .

- Risk of

damage to sensitive electronic components or equipment due to the

discharge of static electricity.

- Risk of

coming into contact with energized conductors of low to moderate voltage

(e.g., 220 volts or less).

- Type of

walking surface and environmental conditions workers may be exposed to

(e.g., loose ground cover, smooth surfaces, temperature, wet/oily,

chemicals, etc.).

Also, evaluate the risk:

- to ankles

from uneven walking surfaces or rough terrain

- of foot

injury due to exposure to extreme hot or cold

- of slips and

falls on slippery walking surfaces

- of exposure

to water or other liquids that may penetrate the footwear causing damage

to the foot and the footwear

- of exposure

to rotating or abrasive machinery (e.g., chainsaws or grinders)

What should I

know about the fit and care of safety footwear?

Fit:

- Try

on new boots around midday. Feet normally swell during the day.

- Walk

in new footwear to ensure it is comfortable.

- Boots

should have ample toe room (toes should be about 12.5 mm from the front).

Do not expect footwear to stretch with wear.

- Make

allowances for extra socks or special arch supports when buying boots. Try

on your new boots with the supports or socks you usually wear at work.

Check with the manufacturer if adding inserts affects your level of

protection.

- Boots

should fit snugly around the heel and ankle when laced.

- Lace

up boots fully. High-cut boots provide support against ankle injury.

Care:

- Use

a protective coating to make footwear water-resistant.

- Inspect

footwear regularly for damage (e.g., cracks in soles, breaks in leather,

or exposed toe caps).

- Repair

or replace worn or defective footwear.

- Electric

shock resistance of footwear is greatly reduced by wet conditions and with

wear.

- Footwear

exposed to sole penetration or impact may not have visible signs of

damage. Replacing footwear after an event is advisable.

What symbols

will be on the footwear?

The following symbols, or markings, will help you

determine which footwear is appropriate for the job.

|

Selection

of Safety Footwear

|

||

|

Marking

|

Criteria

|

Intended

Application

|

|

Green

triangle indicates sole puncture protection with a Grade 1 protective toecap.

|

For

heavy industrial work environments, especially that of construction where

sharp objects (such as nails) are present.

|

|

Yellow

triangle indicates sole puncture protection with a Grade 2 protective toecap.

|

For

light industrial work environments requiring puncture protection as well as

toe protection.

|

|

Blue

rectangle indicates a Grade 1 protective toecap with no puncture-resistant

sole.

|

For

industrial work environments not requiring puncture protection.

|

|

Grey

rectangle indicates a Grade 2 protective toecap with no puncture-resistant

sole.

|

For

industrial and non-industrial work environments not requiring puncture

protection.

|

|

White

rectangle with orange Greek letter omega indicates electric-shock protective

footwear.

|

For

industrial work environments where accidental contact with live electoral

conductors can occur. Warning: Electrical

shock resistance deteriorates with wear and in a wet environment.

|

|

Yellow

rectangle with black SD letters indicates static-dissipative footwear.

|

For

industrial work environments where a static discharge can create a hazard for

workers or equipment. Warning: This

footwear should not be used where contact with live electrical conductors can

occur.

|

|

Yellow

rectangle indicates sole puncture protection with a Grade 2 protective

toecap. (super-static dissipative footwear)

|

For

industrial work environments where a static discharge can create a hazard for

workers or equipment. Warning: This

footwear should not be used where contact with live electrical conductors can

occur.

|

|

Red

rectangle with white C letter indicates electrically conductive footwear.

|

For

industrial work environments where low-power electrical changes can create a

hazard for workers or equipment. Warning: This

footwear should not be used where contact with live electrical conductors can

occur.

|

|

Dark

grey rectangle with M letter indicates metatarsal protection. Note: Toe protection is required for all

metatarsal protective footwear.

|

For

industrial work environments where heavy objects can hurt the metatarsal

region of the foot.

|

|

White

label with green fir tree symbol footwear provides protection when using

chainsaws.

|

For

forestry workers and others who work with or around hand-held chainsaws and

other cutting tools.

|

NOTE: Footwear will also be marked to indicate

the level of slip resistance. These markings may be on the packaging, the

footwear, or on a product sheet.

To buy original safety footwear or safety boots,

shoes in Nigeria, visit: Safety Zone Nigeria at www.safetyzone-ng.com or call:

07030398999

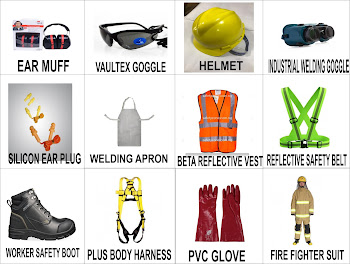

For your safety shoes, safety boots, helmet, coverall,

nose mask, safety wears and other safety equipment or products in Nigeria.

Pls visit: www.safetyzone-ng.com or call 07030398999.

Comments

Post a Comment