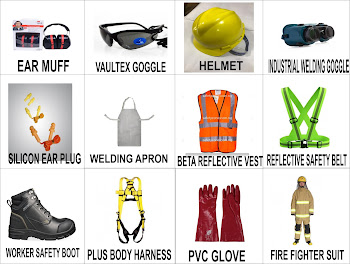

PERSONAL PROTECTIVE EQUIPMENT (PPE)

The primary methods for preventing employee

exposure to hazardous materials are elimination, engineering and administrative

controls. Where these control methods are not appropriate or sufficient to

control the hazard, personal protective equipment (PPE) is required.

A work area assessment is required to determine the potential hazards and select the appropriate PPE for adequate protection. Employees must receive training which includes the proper PPE for their job, when this PPE must be worn, how to wear, adjust, maintain, and discard this equipment, and the limitations of the PPE. All training must be documented.

Objective

To ensure the proper selection,

use, and care of PPE through work area hazard assessments and appropriate

employee training.

Each department is responsible

for:

1. Identifying the appropriate PPE

based on the hazards of the task/ work area. See PPE Selection Considerations in the EHSC

home page to assist you with this assessment.

2. Providing and paying for required PPE. Assure appropriate equipment is available

3. Enforcing the proper use of PPE

4. Maintaining PPE in a clean and reliable condition (clean, sanitary, replace worn or defective parts)

5. Training employees (document the training) on the following:

2. Providing and paying for required PPE. Assure appropriate equipment is available

3. Enforcing the proper use of PPE

4. Maintaining PPE in a clean and reliable condition (clean, sanitary, replace worn or defective parts)

5. Training employees (document the training) on the following:

a.

When PPE is needed

b. What PPE is needed

c. How to properly put on, adjust, wear, and remove the PPE

d. Useful life and limitations of the PPE

e. Proper care, storage, and disposal of the PPE

b. What PPE is needed

c. How to properly put on, adjust, wear, and remove the PPE

d. Useful life and limitations of the PPE

e. Proper care, storage, and disposal of the PPE

Faculty, staff, students,

contractors, and visitors shall wear the appropriate eye and face protection

when working with or around hazardous chemicals/materials/equipment including

but not limited to:

·

Handling of hot solids, liquids,

or molten metals

·

Flying particles from chiseling,

milling, sawing, turning, shaping, cutting, etc.

·

Heat treatment, tempering, or kiln

firing of any metal or other materials

·

Lasers

·

Intense light radiation (UV and

IR) from gas or electric arc welding, glassblowing, torch brazing, oxygen

cutting, etc.

·

Repair or servicing of any vehicle

·

Working with or around chemicals

and gases

Eye protection choices include the

following:

Ordinary prescription glasses do

not provide adequate protection. Eye protection must conform to the American

National Standards Institute (ANSI), Standard Z87.1-1989. Look for this stamp

on the inside of the safety glass frame. Prescription safety glasses are recommended

for employees who must routinely wear safety glasses in lieu of fitting safety

glasses over their personal glasses. All safety glasses shall have side

protection. Whenever protection against splashing is a concern, "Chemical

Splash Goggles" must be worn. See the Eye and Face Protection Selection Guide for

further information.

Use -

Goggles are intended for use when protection is needed against chemicals or particles.

Impact protection goggles which contain perforations on the sides of goggle are

not to be used for chemical splash protection, therefore are not recommended.

Splash goggles which contain shielded vents at the top of the goggle are

appropriate for chemical splash protection, and also provide limited eye impact

protection. Goggles only protect the eyes, offering no protection for the face

and neck. See the Eye and Face Protection Selection Guide for

further information.

Full face shields provide the face

and throat and partial protection from flying particles and liquid splash. For

maximum protection against chemical splash, a full face shield should be used in

combination with chemical splash goggles. Face shields are appropriate as

secondary protection when implosion (e.g. vacuum applications) or explosion

hazards are present. Face shields which are contoured to protect the sides of

the neck as well as frontal protection are preferred. See the Eye and Face Protection Selection Guide for

further information.

(welding, glassblowing, gas welding,

oxygen cutting, torch brazing, laser use, etc.)

The radiation produced by welding covers a broad range of the spectrum of light. Exposure to ultraviolet light (UV-B) from welding operations can cause "welders flash", a painful inflammable of the outer layer of the cornea. Arc welding or arc cutting operations, including submerged arc welding, require the use of welding helmets with an appropriate filter lens. Goggles with filter plates or tinted glass are available for glassblowing and other operations where intense light sources are encountered, including but not limited to, gas welding or oxygen cutting operations. Spectacles with suitable filter lenses may be appropriate for light gas welding operations, torch brazing, or inspection. See Filter Lenses for assistance in selection of appropriate shade selection. Users and visitors to Laser use areas (the laser nominal hazard zone) must be protected with suitable laser protection eye wear. Contact the laser manufacturer or the NCSU laser safety officer (919-515-6860) for assistance in selecting laser eye wear. See Class 3b and Class 4 Lasers for further information on lasers.

The radiation produced by welding covers a broad range of the spectrum of light. Exposure to ultraviolet light (UV-B) from welding operations can cause "welders flash", a painful inflammable of the outer layer of the cornea. Arc welding or arc cutting operations, including submerged arc welding, require the use of welding helmets with an appropriate filter lens. Goggles with filter plates or tinted glass are available for glassblowing and other operations where intense light sources are encountered, including but not limited to, gas welding or oxygen cutting operations. Spectacles with suitable filter lenses may be appropriate for light gas welding operations, torch brazing, or inspection. See Filter Lenses for assistance in selection of appropriate shade selection. Users and visitors to Laser use areas (the laser nominal hazard zone) must be protected with suitable laser protection eye wear. Contact the laser manufacturer or the NCSU laser safety officer (919-515-6860) for assistance in selecting laser eye wear. See Class 3b and Class 4 Lasers for further information on lasers.

Employees shall use hand

protection when exposed to hazards including:

Skin absorption of harmful

substances

Lacerations

Severe cuts

Severe abrasions

Punctures

Chemical burns and irritation

Thermal burns

Harmful temperature extremes

Lacerations

Severe cuts

Severe abrasions

Punctures

Chemical burns and irritation

Thermal burns

Harmful temperature extremes

Wear proper hand protection

whenever the potential for contact with chemicals, sharp objects, or very hot

or cold materials exists. Select gloves based on the properties of the material

in use, the degree of protection needed, and the nature of the work (direct

contact necessary, dexterity needed, etc.). Check the Hand Protection Reference Guide for

assisting you in selecting the proper gloves for your task. Leather gloves may

be used for protection against sharp edged objects, such as when picking up

broken glassware or inserting glass tubes into stoppers. When working at

temperature extremes, use insulated gloves. Materials such as Nomex and Kevlar

may be used briefly up to 1000 F. Do not use gloves containing asbestos.

Asbestos is regulated as a carcinogen under OSHA. When considering chemical

gloves, note that glove materials will be permeated (pass through) by

chemicals. The permeation rate varies depending on the chemical, glove

material, and thickness. Double gloving is recommended when handling highly

toxic or carcinogenic materials. Before each use, inspect the gloves for

discoloration, punctures and tears. Before removal, wash gloves if the glove

material is impermeable to water. Observe any changes in glove color and

texture, including hardening or softening, which may be indications of glove

degradation. The Fact Sheet section of the EHSC home page contains

a Skin Protection checklist, which is a

short summary of skin protection factors to consider.

Employees working around hazard

materials or machinery shall not wear loose clothing (e.g. saris, dangling

neckties, necklaces ) or unrestrained long hair. Loose clothing, jewelry, and

unrestrained long hair can become ensnared in moving parts of machinery or

contact chemicals. Finger rings can damage gloves and trap chemicals against

the skin.

Where contact with hazardous materials with your protective clothing is likely, such as during spill cleanup or pesticide application, polyethylene- coated Tyvek or similar protective clothing should be used to provide additional protection . The limitations of the protective clothing must always be understood, particularly in situations where contact with the material is likely.

Where contact with hazardous materials with your protective clothing is likely, such as during spill cleanup or pesticide application, polyethylene- coated Tyvek or similar protective clothing should be used to provide additional protection . The limitations of the protective clothing must always be understood, particularly in situations where contact with the material is likely.

Employees should know the appropriate techniques for removing protective apparel, especially any that has become contaminated. Special procedures may need to be followed for cleaning and/or discarding contaminated apparel. Chemical spills on leather clothing accessories (watchbands, shoes, belts and such) can be especially hazardous because many chemicals can be absorbed in the leather and then held close to the skin for long periods. Such items must be removed promptly and typically be discarded to prevent the possibility of chemical burns. In addition, protective aprons and sleeves may be required when working with large volumes of corrosive material.

Lab Coat Selection

Buttoned, long lab coats are required in all NCSU laboratories at all times to minimize clothing contamination and skin exposure to hazardous chemicals. They also provide some temporary protection against fire. 100% cotton lab coats are the minimum required body protection in labs. Polyester or poly-cotton blend lab coats may be acceptable, but only after being approved by EH&S for a specific application. Although, most lab coats are not designed to be impermeable to hazardous substances or flameproof, they provide additional safety because they can be quickly removed to isolate harmful exposures or flames.

To minimize body exposures in the lab and provide some temporary protection against fire, adhere to the following:

Buttoned, long lab coats are required in all NCSU laboratories at all times to minimize clothing contamination and skin exposure to hazardous chemicals. They also provide some temporary protection against fire. 100% cotton lab coats are the minimum required body protection in labs. Polyester or poly-cotton blend lab coats may be acceptable, but only after being approved by EH&S for a specific application. Although, most lab coats are not designed to be impermeable to hazardous substances or flameproof, they provide additional safety because they can be quickly removed to isolate harmful exposures or flames.

To minimize body exposures in the lab and provide some temporary protection against fire, adhere to the following:

1. Be

aware of limitation of each type of the lab coat

2. Make

sure that additional protective measures are selected and in use based on the

hazard reviews

3. Lab

coats may not be taken home to be laundered. They are not to be worn in public

places such as offices, classrooms not associated with labs, break rooms,

bathrooms, etc.

4. Contact

EH&S for any questions (919-513-1282)

5. Read NCSTATE University Lab coat Selection

Guideline and select your lab coat based on the type of the

lab activities/hazardous material used.

6. Only

long pants are to be worn with lab coats, no shorts.

Safety toe footwear shall conform

to the requirements and specifications of ASTM-F 2413 March 2005,

"American Standard Test Method"

Wear proper shoes, not sandals or

open toed shoes, in work areas where chemicals are used or stored. Perforated

shoes, sandals or cloth sneakers should not be worn in areas where mechanical

work is being done.

Safety shoes are required for

protection against injury from heavy falling objects (handling of objects

weighing more than fifteen pounds which, if dropped, would likely result in a

foot injury), against crushing by rolling objects (warehouse, loading docks,

etc), and against laceration or penetration by sharp objects.

The state personal protective

equipment policy stipulates that employees who are required to wear safety

shoes will be eligible for departmental reimbursement up to $100.

Pullovers, worn over regular

shoes, are available for protection against certain chemicals. These boots are

made of a stretchable rubber compound and are well suited for cleaning up

chemical spills.

There is also specific information

on Foot Protection available.

See the Respiratory Protection section of this

Health and Safety manual for more information. Respirators may not be used without

prior approval from the Industrial Hygiene section (919-515-6862) of the

Environmental Health and Safety Center. This assures that respirators are

properly selected, users are properly trained, and the appropriate medical

exams are conducted according to OSHA regulations.

Exposure to noise in excess of 85

dBA for 8 hours requires participation in a hearing conservation program. This

program includes training and audiometric exams, among other requirements.

Please contact EHSC at 919-515-6862 if you feel your noise exposure may be

excessive. The Hearing Conservation section of this

Health and Safety manual for more information.

Helmets designed to protect the

head from impact and penetration from falling/flying objects and from limited

electric shock and burn shall meet the requirements and specifications

established in ANSI Z89.1- 1986, "Requirements for

Industrial Head Protection". For more information contact EHSC

at 919-513-0988.

Specific design and performance,

use, and care requirements apply to protective equipment used for isolation

against electrical hazards. Persons selecting for purchase, maintaining, and

using such equipment (insulating blankets, matting, covers, line hose, gloves,

and sleeves made of rubber) must be familiar with these requirements (refer to

29 CFR 1910.137). See the Electrical Safety section of this Health

and Safety manual or contact EHSC at 919-513-0988 for additional information. Lockout / Tagout procedures must be

followed and any live electrical work will require a permit.

To buy original safety footwear or

safety boots, shoes in Nigeria, visit: Safety Zone Nigeria at www.safetyzone-ng.com or call:

07030398999

For

your safety shoes, safety boots, helmet, coverall, nose mask, safety wears

and other safety equipment or products in Nigeria. Pls visit: www.safetyzone-ng.com or call 07030398999.

Comments

Post a Comment