THE NEED FOR PERSONAL PROTECTIVE EQUIPMENT IN WORKPLACE

THE NEED FOR PERSONAL PROTECTIVE EQUIPMENT IN WORKPLACE

INTRODUCTION

Many times workers do not adhere to personal protective equipment (PPE) requirements because they feel it is a nuisance to wear or slows them down during a task. But PPE is used only when some type of hazard has been identified and cannot be eliminated or controlled through other means. Simply stated, when we have personal protective equipment requirements, it means there is a hazard that may cause you injury and failing to use the prescribed equipment puts you in potential danger.

PROTECTING YOU FROM HAZARDS

Personal protective equipment is NOT the first line of defence against identified hazards at our workplace. We make every attempt to engineer solutions to prevent injuries so PPE isn’t necessary. When we can’t fully eliminate or control the hazard, then we provide PPE for your safety.

WHEN AND WHERE IS PROTECTION REQUIRED?

The company assesses all the work areas to find the hazards that are present, or might be present at some time, and then makes protective equipment decisions based on those assessments. This is an ongoing process to make sure we are always current and aware of the hazards of our work environment. Supervisors will keep you informed of the type of PPE for your work area or the specific jobs you perform. If you notice a hazard that could potentially require PPE to maintain your safety, don’t hesitate to talk to your supervisor.

PROPER USE

No PPE will do you any good unless it is sized correctly and fitting properly. This may sound elementary, but everything from gloves to shoes to glasses to goggles must fit the right way in order for it to properly protect you. This is why you need to take some time to make sure all of your PPE is the correct size. If some equipment doesn’t fit in the right way, wearing it is not doing you any good at all.

PPE HAS ITS LIMITATIONS

PPE is effective when it is used as designed. For instance, not all gloves protect against all hazards: leather gloves provide good protection against cuts and slivers but do nothing for chemical safety. Safety glasses protect your eyes but not the rest of your face. For each type of PPE, it is important to know what it will guard against and what it won’t.

PROPER CARE AND MAINTENANCE

PPE that is not properly maintained will not last long and will not protect you. In fact, poorly maintained equipment can be a greater hazard: glasses that are dirty create visibility problems, chemical gloves with pin holes will allow chemicals to touch your skin and shoes held together by tape won’t protect your feet and will create trip hazards. Before each use, inspect equipment for potential problems, and never use damaged PPE. Contact your supervisor and only proceed with the task when you are equipped with properly maintained PPE. When you are done using the gear, clean it up so it is ready for the next use.

HAND PROTECTION

The one thing to remember with gloves is there is no one glove that provides protection for every type of hazard. Knowing both the hazard you are guarding against and the type of protection required ensures you will properly protect your hands in all circumstances. Most gloves are designed for a specific hazard or task.

Gloves used for chemical protection are not good for general tasks or with every type of chemical. Just because a glove is right for one type of chemical doesn’t mean it provides adequate protection for every chemical. It is important to match the right glove to the chemicals you are working with.

General work gloves, such as leather gloves, are good for protection against cuts, slivers and blisters but won’t protect against electrical shock or chemical exposure. Leather gloves are also appropriate when handling rough materials.

Cut-resistant gloves are designed to improve your grip when holding oily, metal parts and to protect hands against metal burrs or other cut hazards. They won’t provide protection against corrosive chemicals.

Depending on your task, you may need more than one pair of gloves to guard against different types of hazards. Your supervisor will help you with all your glove selections.

EYE AND FACE PROTECTION

Safety glasses must have side shields that are mounted to the frame. The glasses themselves should be adjusted so they fit properly around your ears and on your nose so they don’t slide down while you are working. Face shields provide protection for the whole face where glasses only protect the eyes. They have adjustment ratchets on the headband that must be adjusted to the individual user’s head. Goggles provide good protection for eyes against dusts and mists. They should be adjusted properly so they fit snug on your face and there are no gaps between the goggle and your face. Vented goggles help to prevent goggles from fogging up in warm conditions.

HEAD PROTECTION

Proper head protection is required in some areas where there is a hazard for falling and flying objects or a risk of electrical shock. Especially in storage areas, the risk of falling products and materials is high. Wearing properly fitting PPE in these required areas is essential to your safety.

FOOT PROTECTION

When steel-toed safety shoes are required, make sure they are used in designated areas. When purchasing steeltoed safety shoes, make sure the shoe is commercial-grade and the metal toe will not collapse if struck

SUMMARY

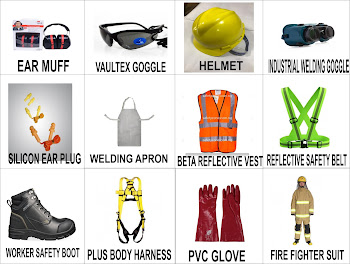

There are many different types of PPE that will help keep you safe. Make sure you are always wearing the right equipment for the right job. Make sure all the equipment is adjusted properly and that you keep all the protective equipment clean. Never use any equipment that is broken or is not working properly. Damaged protective equipment provides no protection at all. You can buy the best and quality Personal Protective Equipment (PPE) at www.safetyzone.com.ng or call: +2347030398999 or 09096864100

Comments

Post a Comment